Main Advantages of

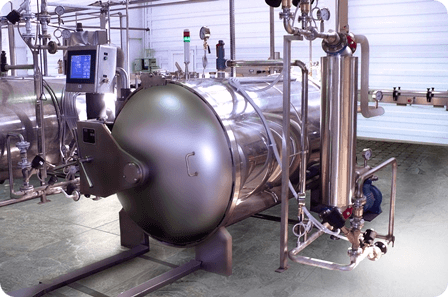

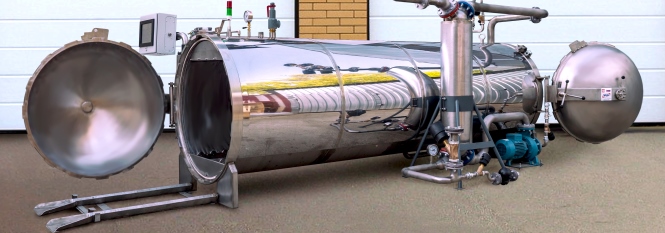

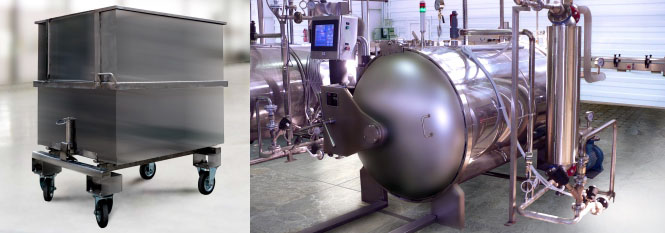

Autoclaves AH-1200

Autoclaves of the AH-1200 series are developed and manufactured in the city of Snezhinsk of Chelyabinsk region by the UralCenterKomplekt LLC enterprise. Leading experts of the enterprise – natives of the Russian Federal Nuclear Center, having a wide experience in creation of highly reliable modern equipment. Principle of work of the enterprise: "We either make well or we don't make at all".

- Autoclaves completely conform to requirements of Rules for the Construction and Safe Operation of the vessels working under pressure, are protected by the Declaration of compliance to technical regulations of the HARDWARE, conform to requirements of technical regulations and EU standards.

- The double-circuit system of heating/cooling is equipped with the heat exchanger of spiral type with high efficiency, and also the powerful circulation pulser which in aggregate provide optimum conditions of heating/sterilization/cooling of production in the autoclave, minimize temporary parameters of process of sterilization (pasteurization) and exclude water losses. It allows to use our autoclaves in the scheme of reverse water supply and to achieve almost waste-free technology.

- Depending on a type of packaging of a sterilized (pasteurized) product, autoclaves of the AH-1200 series are equipped either douche system, or the system creating in the autoclave a steam-and-water cloud by means of system of nozzles. The douche system provides a highly effective heat transfer, and also uniformity of distribution of "rain" on the autoclave length that is necessary for the guaranteed observance of a mode of sterilization (pasteurization) of production in any point of volume of the autoclave.

- Reliability of executive elements of the control system is provided with use of the most modern and hi-tech valves with pneumomanagement.

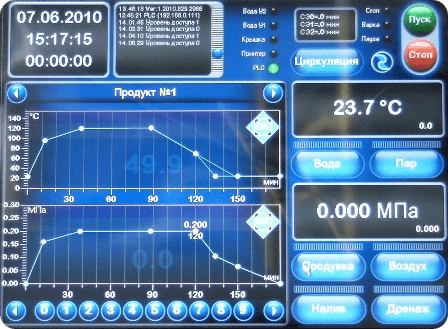

- Use as a kernel of a control system of the industrial computer with the touch screen provides reliable input and evident submission of information on the screen in the course of all cycle of sterilization, creation and maintaining a full-fledged database (archive) both on standard modes of sterilization, and on concrete cookings (practically without restriction of volume of stored data). Feature of a control system is the "friendly" and clear interface of communication with the operator, allowing quickly to train the operator and to provide convenience of perception of information in the course of work.

- All autoclaves of the AH-1200 series are equipped with three-stage safety system preventing opening of the autoclave door in the presence of excessive pressure inside it.

- At short-term losses of power supply the control system allows to continue the current process in an automatic mode. If in the course of work (autoclaving) there was a long interruption in power supply, after its restoration the system allows either to modify the set mode and to continue process in an automatic mode, or to finish sterilizing in a mode of manual control from an operator console.

- Additional option – system for measurement and calculation of effect of sterilization (pasteurization). Allows at working technology of sterilization of a product in new container to take temperature in particular "jars" to calculate sterilizing effect in those jars.

Check the detailed description and technical characteristics of autoclaves AH-1200T.

1

1 2

2 3

3 4

4 5

5 6

6 7

7