Boilerclaves (Autoclaves) BH-1200

for smelting of model structure

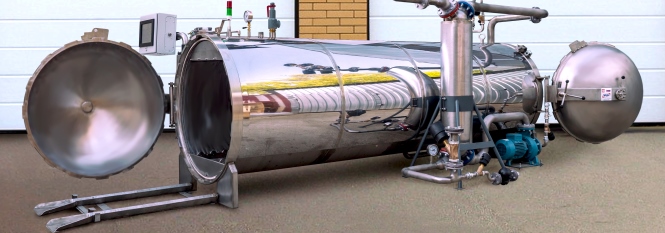

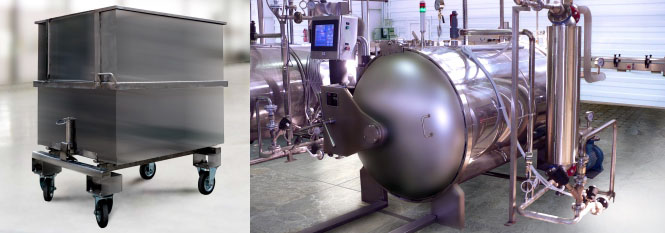

The autoclave of horizontal type from stainless steel is intended for fusion and removal of model structure from ceramic forms in case of production of castings by a casting method on the melted models.

The autoclave allows to make smelting of model structure from ceramic forms of complex configuration. Removal of model structure from ceramic forms is made at a temperature up to 160 °C. Smelting of model structure from small-sized forms and large-size blocks with a diameter up to 750 mm, up to 550 mm high is possible.

All process of removal model composition from ceramic forms is completely automated. The management system is executed on the basis of the panelized computer and provides process control according to the regime cards issued by the technologist. The management system allows to save in archive and to document process parameters, to realize an output of operational information in a graphic view of the monitor. There is a possibility of process control both in automatic, and in a manual mode.

The autoclave is the vessel working under pressure and according to requirements of Rules of Rostekhnadzor is equipped with the corresponding devices of safety.

Opening (closing) of a bayonetny lock is carried out by the convenient mechanical drive installed on the autoclave door.

Technological operations:

- production of steam of necessary parameters (Р =0,5mpa, °C t=160) is made by the completed steam generator.

- opening of a door with a zero pressure in the autoclave and closing of a door;

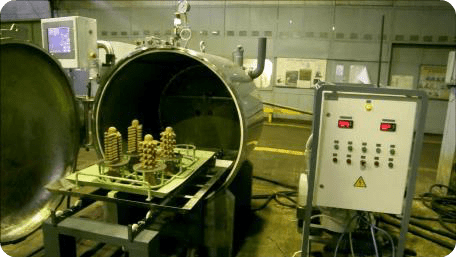

- transportation on the cartridge cart with blocks to the autoclave and from the autoclave;

- loading of the cartridge with blocks in the autoclave;

- steam admission in the autoclave in case of completely closed door;

- endurance of blocks in the autoclave during smelting time (from 5 to 20 min and more);

- dumping of pressure (release of steam);

- release of model structure in the collector;

- unloading of the autoclave.

The main parameters and characteristics are listed in the table below:

| Name of the parameters and characteristics | Value |

|---|---|

| Housing diameter autoclave, mm |

1200 |

| The working volume of the chamber (autoclave), m³ |

1,3 |

| Smelting working environment | Saturated steam |

| Operating pressure, MPa |

0,5 |

| The maximum temperature, °С |

160 |

| The maximum flow rate of steam, kg / h |

Up to 500 |

| The vapor pressure in the pipeline, however, MPa |

Class 0,5 |

| Time-to-work mode, h, no more |

1,0 |

| The largest dimensions of the model-ceramic block mm, diameter x height |

550 x 550 |

| The duration of the cycle of melting, min |

5 - 20 |

| The greatest number of model composition, melted in one cycle, l |

30 |

| Time to pressure in the chamber to 0.4 MPa,

with no more than, with no more than, c |

10 |

| The speed of the pressure relief, MPa/s, max |

0,01 |

| The highest performance units per hour | up to 80 |

| The air pressure in the supply line, however, MPa |

0,5 |

1

1 2

2 3

3 4

4 5

5 6

6 7

7